About us

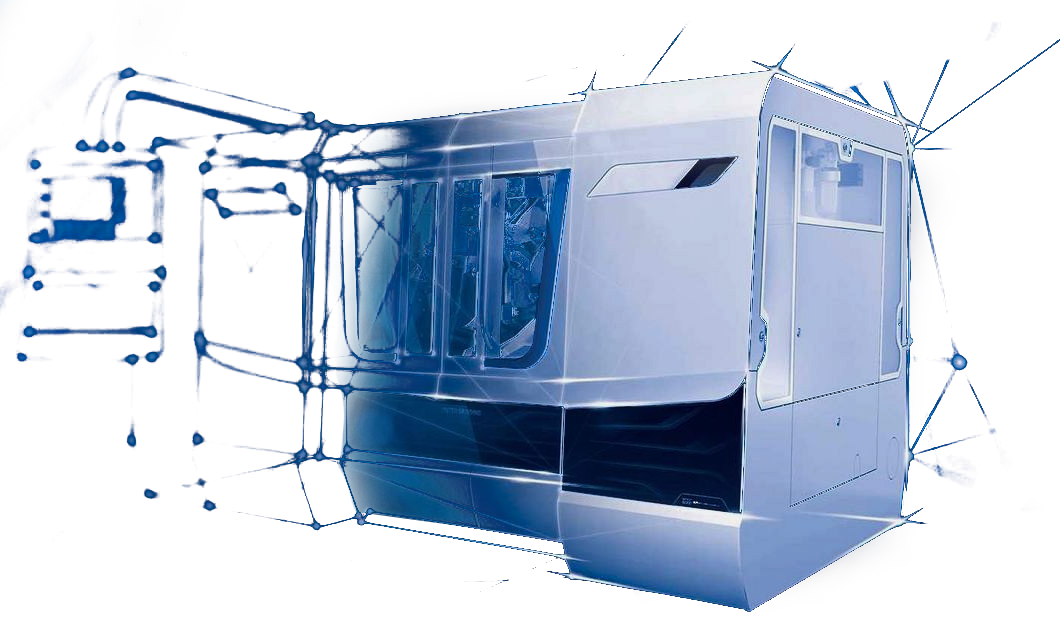

LogPartner was born from the growing need of the market for a differentiated service in the service of CNC's grinding machines, serving the most varied types of equipment and all the brands existing in the national market.

We work with a team of professionals with extensive experience in the field and who seek the most appropriate solutions to strengthen our customers' business more and more.

For several years in the CNC Grinders machines maintenance market, we at LogPartner have worked with an exclusive methodology for this segment, as we follow a pattern of historical analysis and tests already used on other occasions, which guarantees us faster and more efficient diagnosis of problems presented.

For several years in the CNC Grinders machines maintenance market, we at LogPartner have worked with an exclusive methodology for this segment, as we follow a pattern of historical analysis and tests already used on other occasions, which guarantees us faster and more efficient diagnosis of problems presented.